Laser cutting is transforming manufacturing by boosting precision, reducing waste, and speeding up production. This blog highlights how this innovative technology helps manufacturers cut costs and optimize workflows for greater efficiency.

What Is Laser Cutting?

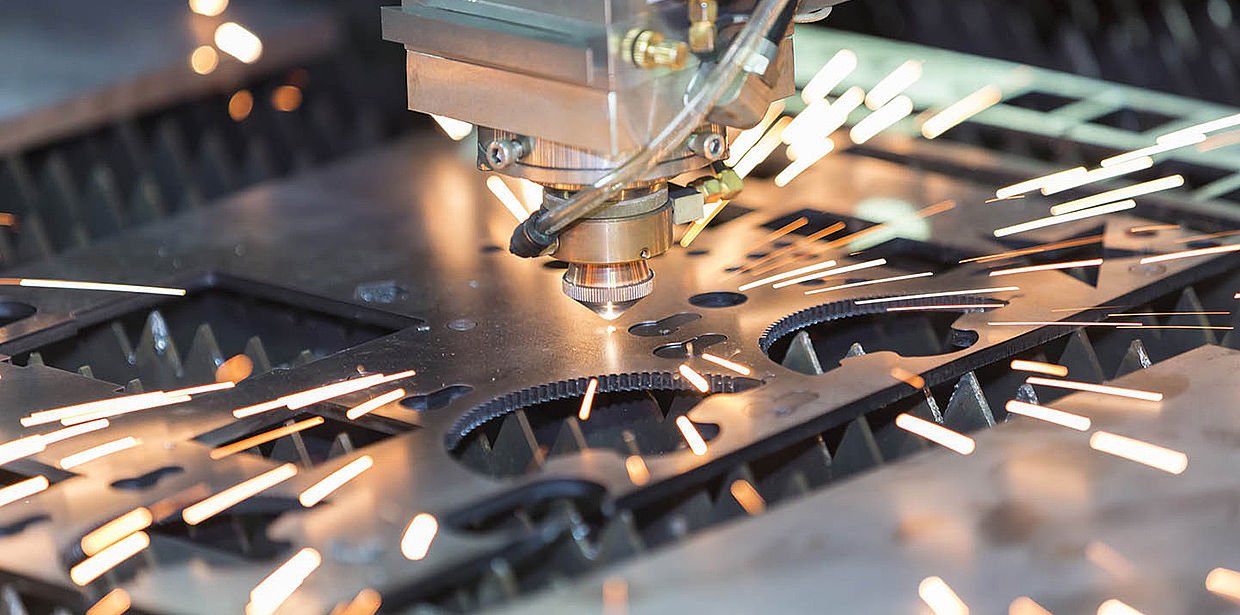

Before we dig into its benefits, let’s cover the basics. Laser cutting is a manufacturing process where a high-powered laser is used to cut, engrave, or shape materials like metals, plastics, or wood. The process involves focusing a laser beam onto the material to melt, burn, or vaporize it, leaving behind smooth, precise edges.

This method is particularly popular in industries like aerospace, automotive, healthcare, fashion, and even electronics because of its versatility and rapid turnaround.

Modern laser cutting machines come equipped with features like computer numerical control (CNC), ensuring that designs are crafted to precise specifications. This automation also allows manufacturers to handle bulk orders, intricate designs, and custom projects without significant downtime.

The Speed Advantage: Reducing Production Time

One of the most obvious benefits of laser cutting is the speed at which tasks can be completed. Here’s how it helps manufacturers meet demanding timelines:

1. Rapid Prototyping

Traditional prototyping methods can take weeks, especially when custom molds need to be created. Laser cutting, on the other hand, enables rapid prototyping directly from a digital file. Operators can quickly modify designs without pausing production, turning ideas into tangible products virtually overnight.

Example: A furniture manufacturer needed to test 10 different chair designs before launching its final version. Thanks to laser cutting, the business was able to create and test all prototypes in just five days, instead of the three weeks traditional methods would have taken.

2. Fast Turnaround for Bulk Orders

Laser cutting machines can perform repetitive tasks quickly and consistently. Whether you need 10 items or 10,000, the machine maintains its efficiency, reducing time spent on labor-intensive setups.

3. Reduced Setup Time

Unlike traditional cutting methods, laser cutting eliminates the need for custom tools, molds, or dies. With advanced CAD (Computer-Aided Design) software, designs can be prepared, adjusted, and implemented without lengthy preparation time.

Bottom Line

Every second saved on the production floor translates directly into faster delivery timelines for your customers.

Financial Gains Through Cost Savings

Reducing production costs is an ongoing priority in every industry, and laser cutting plays a huge part in achieving it. Here are the financial benefits manufacturers can enjoy:

1. Minimized Material Waste

One of the standout features of laser cutting is its precision. The laser beam is extremely narrow and cuts materials with minimal deformation or extra residue. Traditional cutting methods often leave excess material that can’t be reused, whereas laser cutting ensures almost zero waste.

Example

A jewelry designer was able to reduce their material waste by 30% after switching to a laser cutting system, saving thousands of dollars annually.

2. Lower Maintenance Costs

Traditional cutting machines often have multiple moving parts that wear down over time. This leads to frequent repairs and replacement costs. Laser cutting machines, however, use fewer mechanical components, resulting in longer tool life and significantly lower maintenance expenses.

3. Saving on Labor Costs

Laser cutting machines are primarily automated, reducing the need for manual intervention. This makes them an ideal solution for industries such as metal fabrication, like those in Utah. Businesses can reallocate their workforce to other high-priority tasks, optimizing efficiency while keeping payroll costs in check.

Pro Tip

Even small businesses can afford to start using laser cutting by outsourcing to third-party providers, eliminating upfront machine costs altogether.

Precision That Takes You to the Next Level

Laser cutting provides unsurpassed accuracy and detail. But how does this affect your production quality and customer satisfaction?

1. Intricate Designs Made Easy

Whether you’re manufacturing complex parts for aerospace engineering or artistic designs for home décor, laser cutting provides unmatched precision. The level of detail achievable would be difficult, if not impossible, to replicate with more traditional methods.

Impact

Precise designs equal higher quality products—and the quality of your products can be your key differentiator in competitive markets.

2. Consistency Across All Units

Maintaining uniformity in large-volume production can be tricky. Laser cutting ensures that every item adheres to the exact same specifications, resulting in reliable, consistent-quality output.

3. Smaller Tolerances

For industries requiring extreme precision, such as medical devices or microelectronics, tight tolerances are non-negotiable. Laser cutting delivers unparalleled accuracy to meet these demands.

Fun Fact

Some industrial laser machines offer tolerances so fine that they can deliver cuts within 0.001mm accuracy—thinner than a strand of human hair!

Versatility Across Multiple Materials

Perhaps the most compelling reason for adopting laser cutting is its versatility. The process can handle a wide range of materials including:

- Metals (steel, aluminum, titanium, etc.)

- Woods (plywood, hardwood, MDF)

- Plastics (acrylics, polycarbonate, polyethylene)

- Textiles (fabrics for fashion or upholstery)

- Glass and ceramics (carefully engraved designs)

This wide array of material compatibility makes laser cutting invaluable in industries as diverse as aviation to custom apparel.

Example

Imagine a branding agency creating custom metal signage for clients. Using laser cutting, they can transition seamlessly from cutting stainless steel signs to engraving a personalized glass award—all with a single machine.

Sustainability & Environmental Benefits

Modern businesses are more focused than ever on reducing their environmental footprint, and laser cutting checks all the right boxes.

1. Energy Efficiency

Laser cutters using fiber laser technology are known to consume less energy than traditional cutting systems. Lower energy usage means reduced operational costs and a smaller carbon footprint.

2. Less Waste Generation

Laser cutting inherently generates less waste thanks to its precise cutting capabilities, ensuring that resources are used optimally.

Pro Tip

Make sustainability your selling point! Highlight the eco-friendly advantages of laser cutting to customers who value green production practices.

Conclusion

It’s clear why more businesses are turning to laser cutting. Whether you want to boost efficiency, cut costs, or enhance product quality, laser cutting offers plenty of benefits.