Choosing the right metal fabricator is essential for bringing your designs to life, whether for construction, custom furniture, or automotive parts. This guide highlights key factors to consider, questions to ask, and tips to ensure a successful partnership that meets your project’s needs.

Why Choosing the Right Metal Fabricator Matters

Metal fabrication is a highly specialized process that involves cutting, bending, and assembling metal to meet specific requirements. A qualified metal fabricator can ensure that you achieve precision, durability, and quality while staying on schedule and within budget.

However, the wrong choice can lead to subpar craftsmanship, delays, and increased expenses. That’s why investing time in finding the right partner is essential.

Key Factors to Consider When Choosing a Metal Fabricator

1. Define the Scope of Your Project

Before reaching out to any fabricator, take time to outline the details of your project. Knowing exactly what you need will help you evaluate potential fabricators more effectively. Consider the following questions:

- What type of metal do you need (e.g., stainless steel, aluminum, carbon steel)?

- Do you need custom shapes, unique designs, or specific finishes?

- What’s your project timeline and budget?

By clearly defining your scope, you’ll be better prepared to find a fabricator who is equipped to meet your requirements.

2. Evaluate Expertise and Specialization

Metal fabricators often specialize in certain types of projects or industries. For example, some may excel at architectural designs, while others focus on industrial or automotive parts. Ensure that the fabricator you choose has experience with similar projects to yours.

Ask for their portfolio or examples of previous work. If you’re designing custom furniture, look for a fabricator who can showcase similar pieces. If your project involves high precision, like aerospace components, seek fabricators with advanced technology and machinery to meet exacting standards.

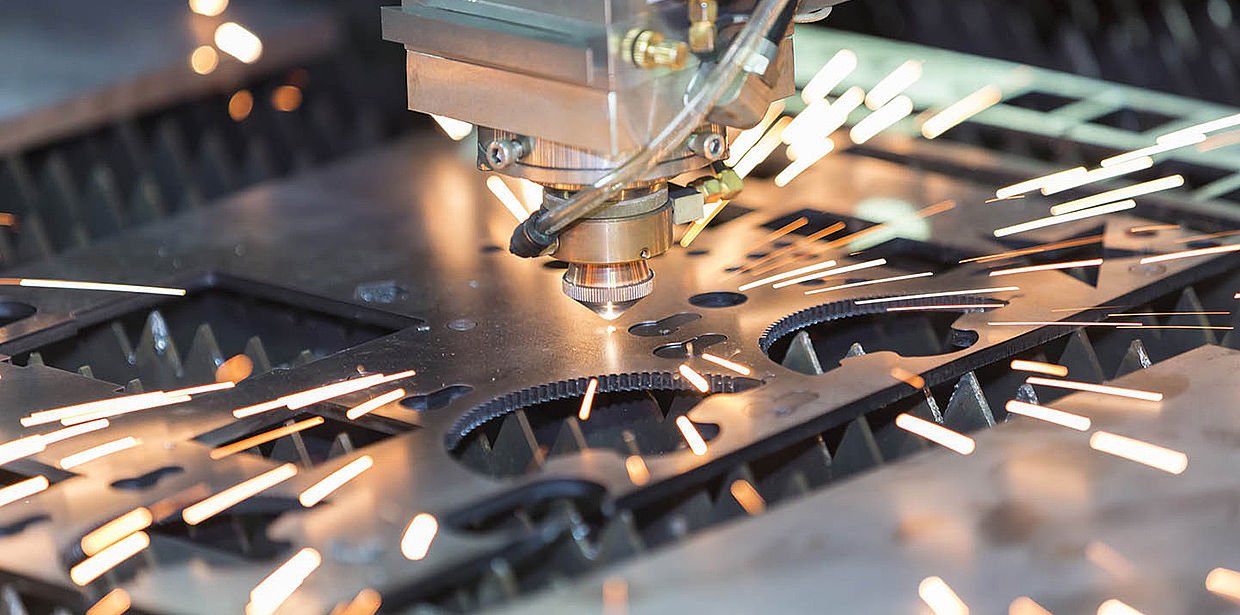

3. Assess Available Equipment and Technology

The capabilities of a metal fabricator heavily depend on the tools and technology they have at their disposal. Fabricators with advanced equipment, such as CNC machines and laser cutting tools, are more likely to deliver high-quality results with accuracy and efficiency.

Modern technology also allows for innovative designs that may not be achievable with manual processes. When interviewing potential fabricators, ask about their machinery and production techniques to ensure they align with your project needs.

4. Check Quality Standards

Quality should always be a top priority. Verify that the fabricator, such as steel fabricators like those in Utah, has licenses, certifications, and compliance with industry standards such as ISO certifications. Reliable fabricators often have robust quality control measures to detect and resolve any issues during production.

Additionally, ask about the materials they use. High-quality projects require premium-grade metals, so ensure the fabricator sources materials from reputable suppliers.

5. Verify Experience with Finishing Processes

Finishing processes like powder coating, welding, and polishing add an essential touch to your finished product. These steps ensure durability, aesthetic appeal, and protection against corrosion or wear.

Confirm that the metal fabricator has in-house finishing capabilities or partnerships with other reliable providers. A one-stop-shop fabricator that handles everything from start to finish can streamline your project and save you time and costs.

Tips for Evaluating and Hiring a Metal Fabricator

Gather Multiple Quotes

Contact several fabricators for detailed quotes on your project. A comprehensive quote should include material costs, labor, timeline estimations, and any additional fees. Avoid choosing a fabricator solely based on the lowest price; instead, focus on the value they bring to your project.

Ask About Lead Times

Ensure the fabricator can handle your project within your desired timeline. Busy fabricators may have longer lead times, which could impact your deadlines. Confirm their availability and discuss penalties or processes if delays occur.

Check References and Reviews

Reputation matters when it comes to metal fabrication. Ask for references or testimonials from previous clients. Online reviews and ratings on platforms like Google or industry-specific directories can also provide helpful insights into the quality of a fabricator’s work.

Set up a Consultation

Meeting potential fabricators in person or virtually is an excellent way to gauge their communication skills, professionalism, and willingness to collaborate. Use this opportunity to ask questions, review their workspace (if possible), and get clarity on their processes.

Benefits of Working with an Experienced Metal Fabricator

When you invest in an experienced metal fabricator, you gain several advantages:

- Precision and Accuracy: Skilled fabricators use advanced tools to deliver accurate results.

- Customization Options: They can cater to unique designs and finishes.

- Time Efficiency: Experienced fabricators streamline the process to meet deadlines.

- Expert Advice: Their industry expertise can help improve your project and avoid costly mistakes.

Common Questions to Ask a Metal Fabricator

To ensure you’re making the right choice, ask potential fabricators the following questions:

- What type of projects do you specialize in?

- Do you have experience with the materials my project requires?

- What is your average lead time?

- Can you provide references or examples of past work?

- Do you offer guarantees or warranties for the finished product?

- What are your quality control measures?

- Do you handle the finishing processes in-house?

The Importance of Collaboration and Communication

A great metal fabrication project isn’t just about technical expertise; it’s also about strong collaboration. Choose a fabricator who is open to feedback and maintains clear, consistent communication throughout the process. This ensures that your project stays on track and any concerns are addressed promptly.

Conclusion

Now that you have a better understanding of what to consider when evaluating and hiring a metal fabricator, you can make an informed decision that best suits your project needs. Remember to prioritize expertise, technology, quality standards, and communication to ensure a successful outcome for your project.